| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HAINA |

| Model Number : | HNJX-UNK600 |

| Certification : | CE |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 72 SETS / Year |

| Delivery Time : | 150 Days |

High Technology I Shape Baby Diaper Machinery In 600 pcs / min

| Machine | High Technology I Shape Baby Diaper Machinery In 600 pcs / min |

| Model | HNJX-UNK600 |

| Products | Baby Diaper |

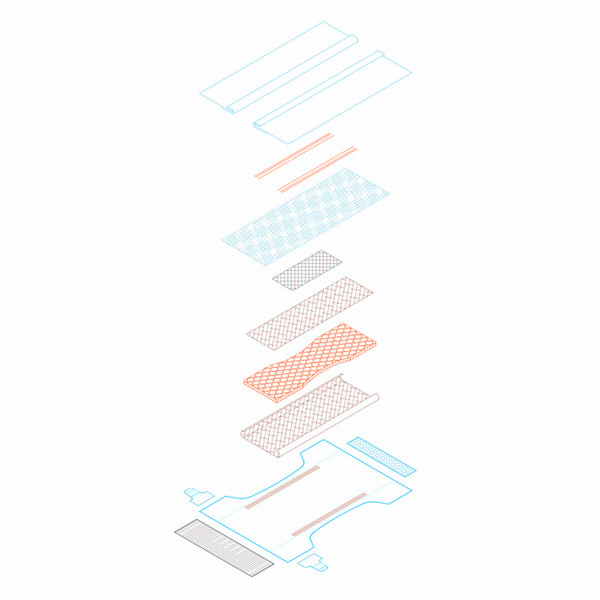

| Products Structure | Upper & Lower tissue paper, Cotton core ( mix with SAP), ADL, PE film, frontal tape, topsheet hydrophilic nonwoven, leg cuff hydrophobic nonwoven, S cut side tape, waistband online. |

| Product Size | NB, S, M, L, XL, XXL |

| Glue Machine | Nordson / Chinese Brands Optional |

| Design speed | 600 pcs/min |

| Production speed | 500 pcs / min |

| Defective rate | ≤3% |

| Efficiency | ≥85% |

| Power Supply | 3 Phase 380VAC, 50HZ (base on customer local power) |

| Total Weight | 100 T customized |

| Power | ~300KW |

| Required Air Compressor | 2m³/min, 0.6-0.8Mpa |

| Dimension | L~42m,W~8.0,H~4m |

| Machine direction | From right to left or left to right (According to the customer requirements) |

| Color | Customized |

Elastic Waist Baby Diaper Schematic View

Features:

Product

Common question:

Q1: How can we get the quotation?

A1: Normally, we will provide offer within 24h, plz contact with us if hurry (Tel & Whatsapp: 008615059553620, Email: becky@fjhaina.com).

Q2: What is the payment term?

A2: 30% deposit before production, 60% before shipment, 10% after installation at buyer's side.

Q3: Where is your factory, how can I visit you?

A3: Haina machinery is located in Jinjiang City, Fujian province, China. You can take the flight to Quanzhou airport, we will go to pick you to our factory.

Q4: What's your after-sale service?

A4: When the machine was shipped from our factory, we will apply visa for engineer at once. When the machine arrives at your factory, we will dispatch them at once.

Q5: Can you provide raw materials?

A5: Sure, we cooperate with many raw material suppliers, they are all reliable suppliers and able to provide very good quality materials.

|